3D WIRE BENDING MACHINE

// some design constraints have been set for the development of the machine.

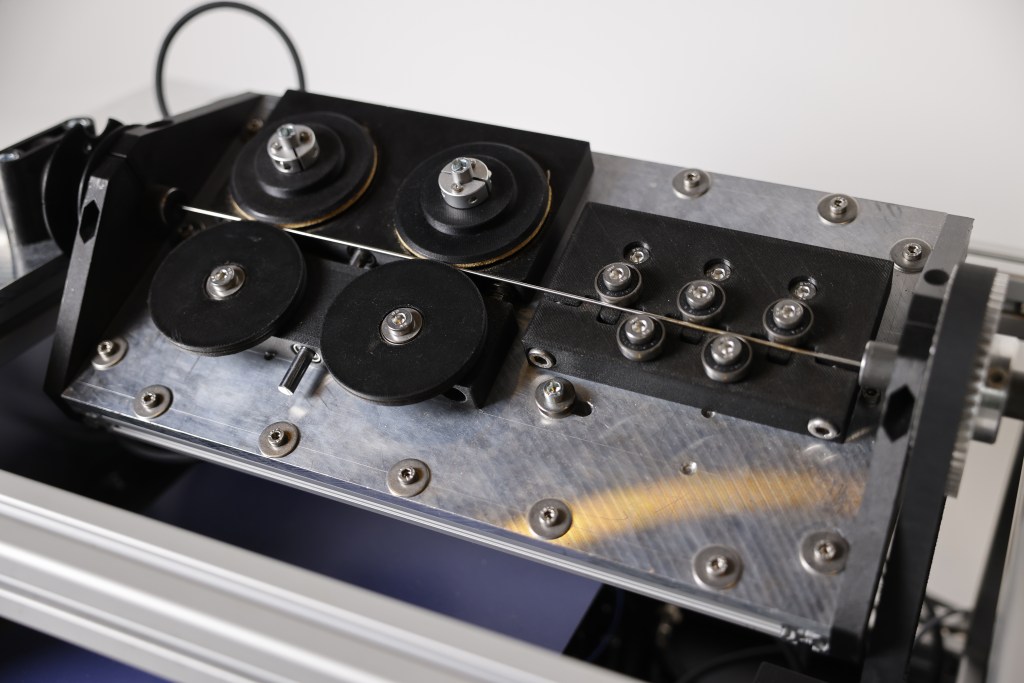

// made only from off the shelve parts and easily produced custom parts.

// custom parts are either 3d printed or aluminium cast plate with drilled and tapped holes.

// only a drill and a 3d printer is needed to manufacture the wire bending machine.

// wire bending or tube bending is rather unconventional manufacturing process for makers.

// the aim of this project is to provide a starting point for DIY wire bending capabilities.

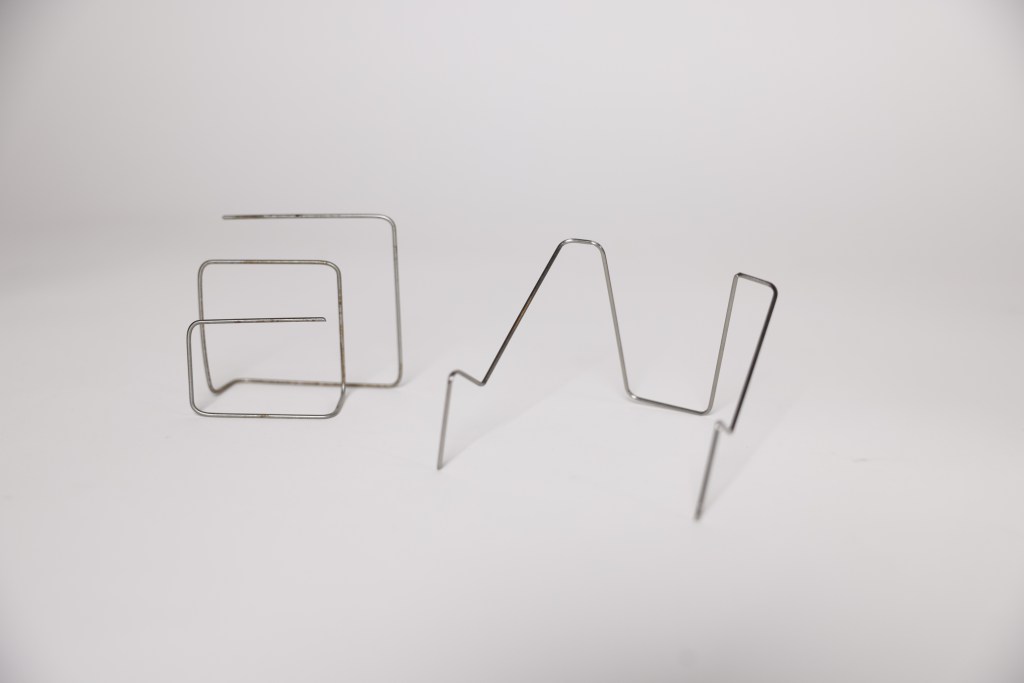

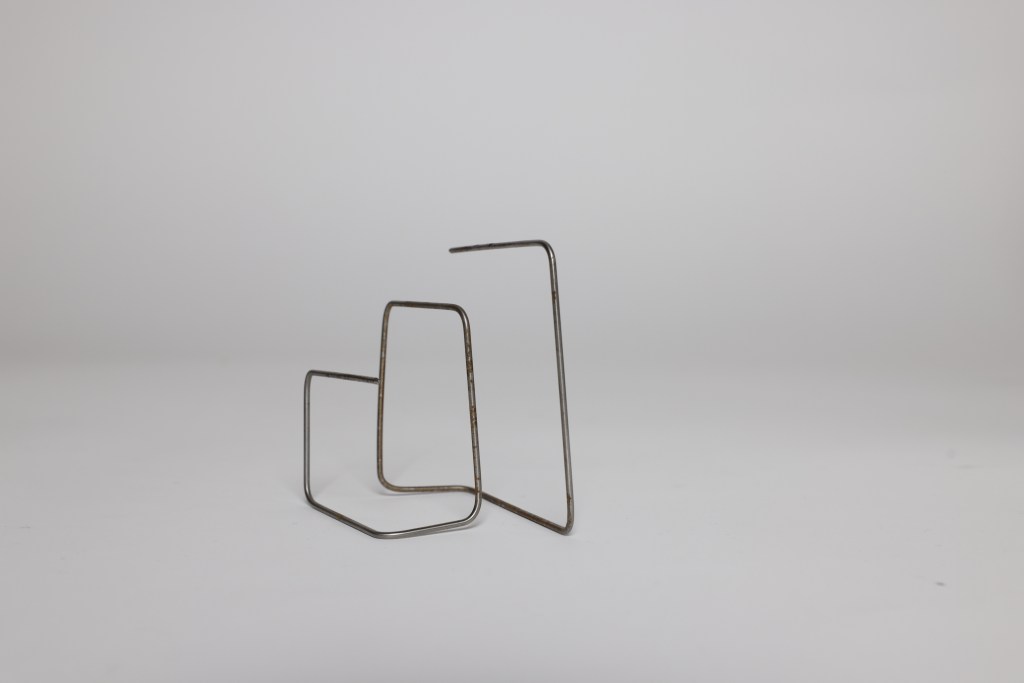

// building this machine can be a great learning opportunity because many different technical concepts are needed for this project // complex three dimensional geometries can be bent with the machine.

// depending on wire material the wire thickness can be up to 6mm in diameter.

// spring steel wire can be bent up to 3mm in diameter.

// the machine has four axis.

// the cnc controller is a sourcerabbit 4-axis controller running rabbitgrbl.

// grbl and the fork rabbitgrbl are a open source cnc control software running on esp32´s.

// closed loop stepper motors on all axis provide high precision and reliability even under high load.

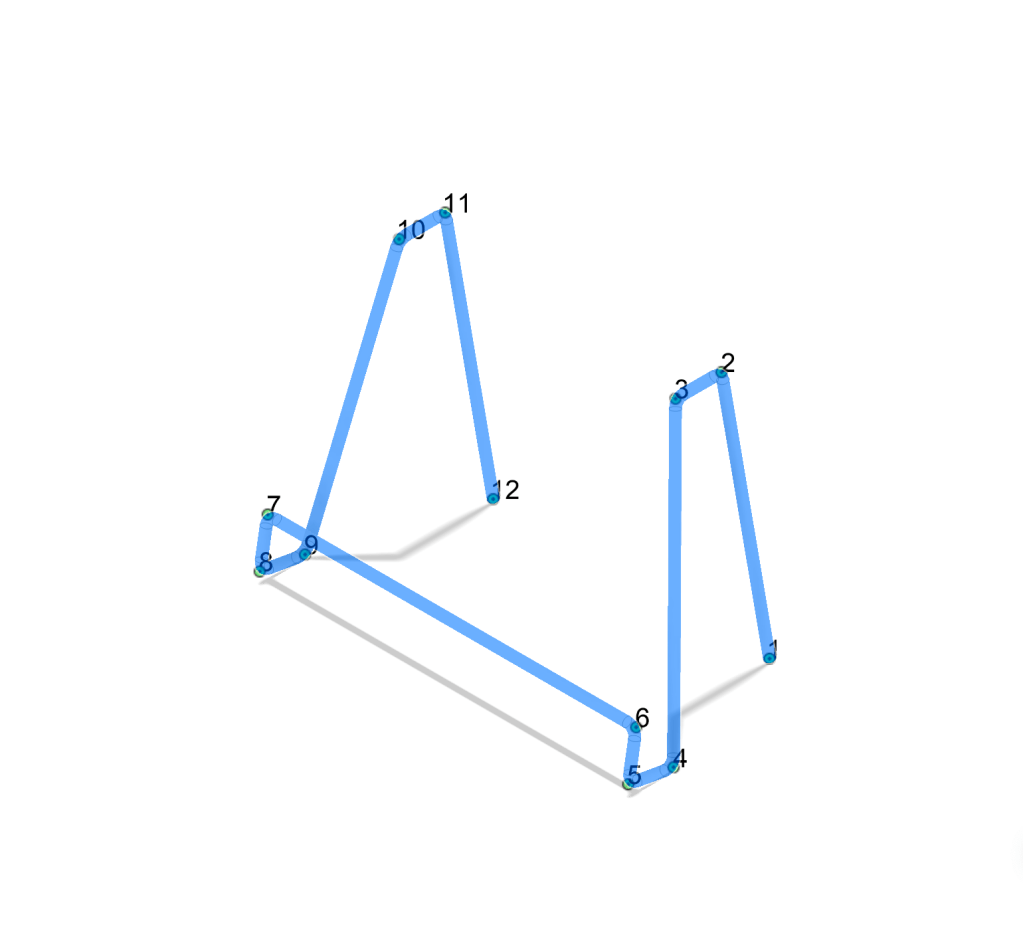

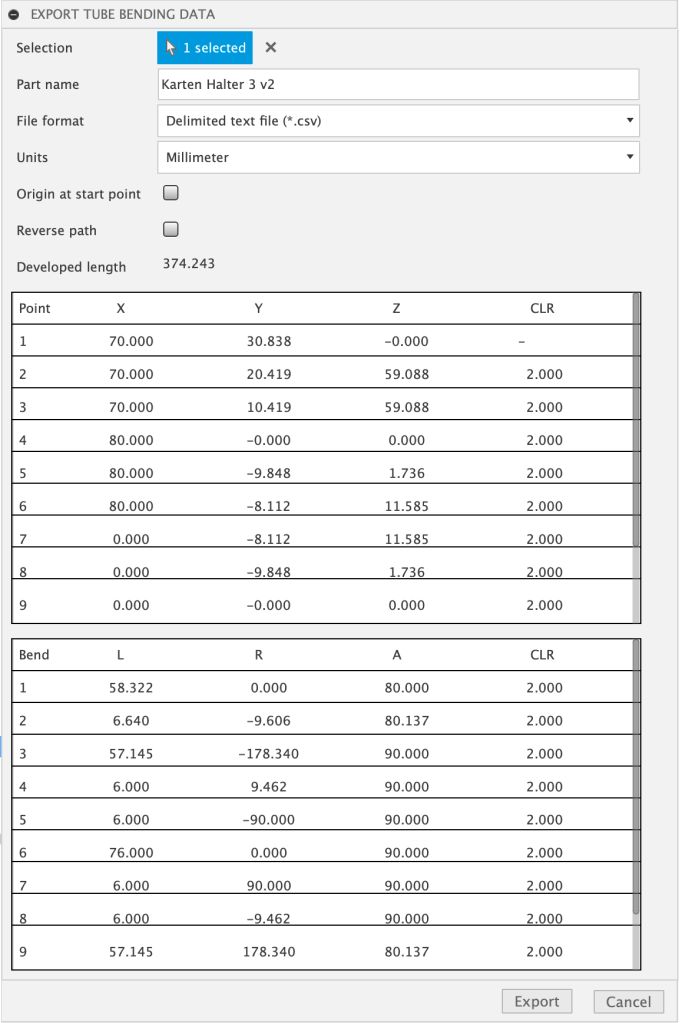

// to create bending data we first need to model the geometry in fusion360.

// then we export the bending data as a .csv file with a add-in called "tube bending data exchanger".

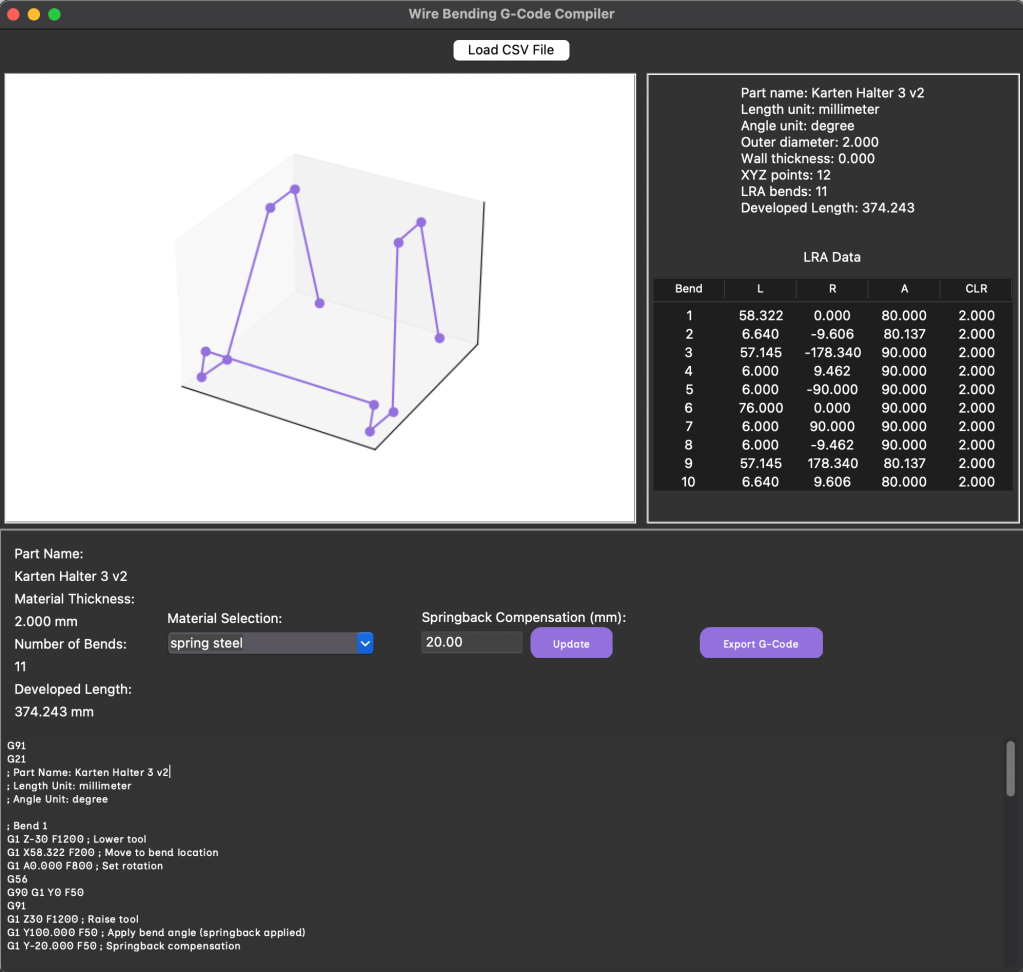

// the .csv file is then processed in a compiler that gives out g code for the wire bending machine.

// in the compiler material and springback compensation can be selected.

// I hope that this machine can be a starting point for wire bending and tube bending to become a more utilised manufacturing technique.

// all files will be released after some clean up of the messy cad assembly.

// the software side of the project can be improved a lot, features like collision detection would enhance the user experience a lot.

// the mechanical side of the project is also far from perfect and version 2 will be a complete redesign // as part of the project "things for thought" by Aeneas Stankowski & Lukas Henneberger

// product design - university of arts berlin 2025

// 3D wire bending machine by Frederic Nishimura